Need a plan quote or proposal? Available for free 24/7!

Contact: +8619914754015 (WeChat/WhatsApp)

Submit your inquiry for a tailored solution.

{{ variable.name }}

Gold in rock gold ores (vein gold ores) often exists in the free state or in the form of natural gold, and the key to efficient recovery lies in realizing the full dissociation of gold from the vein rocks and sorting based on density difference. As a physical beneficiation process with low investment cost, simple operation and maintenance, no chemical pollution, and very high recovery of coarse-grained gold and flake gold, the rock gold ore re-election process is one of the preferred technologies for treating all kinds of rock gold ores (especially quartz vein-type gold ores).

We focus on providing a full set of rock gold re-election solutions from ore characterization, process design, equipment supply to installation and commissioning training, aiming at maximizing the return on investment and greening the production and operation of the core objectives for our customers.

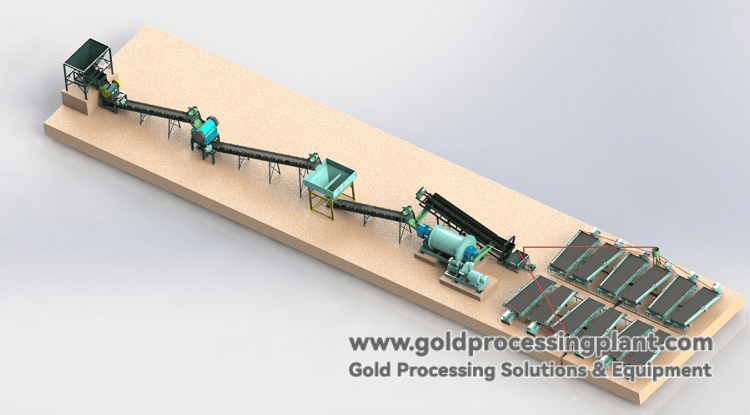

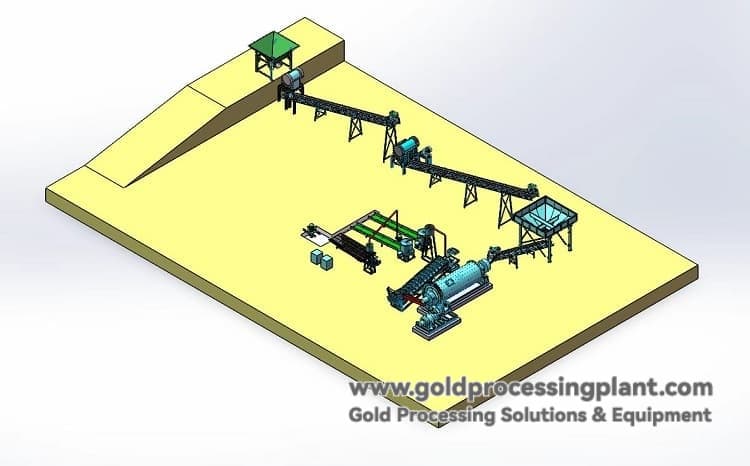

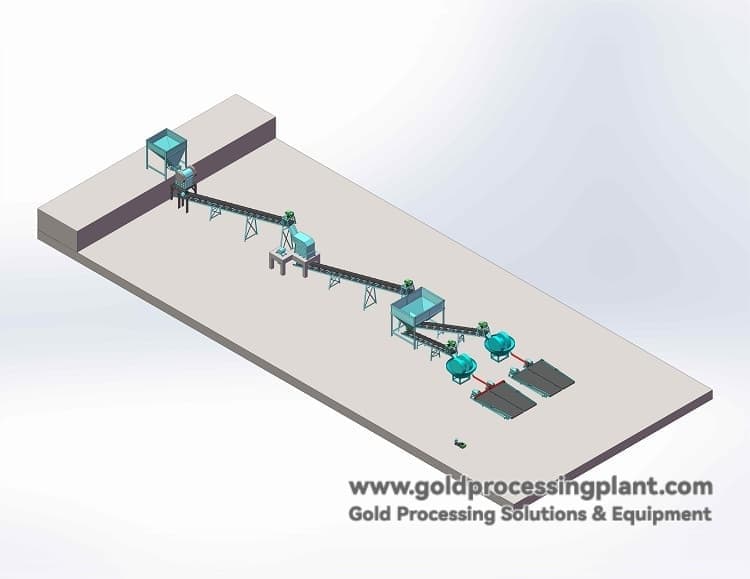

A highly efficient and reliable rock gold processing line usually consists of the following four stages, which are precisely connected to each other:

Stage 1: Crushing System - Laying the foundation for efficient dissociation

Purpose: Gradually crushing the raw ore to a size suitable for grinding, avoiding over-crushing and protecting coarse-grained gold.

Process:

Coarse crushing: Raw ore is fed evenly into the jaw crusher via vibrating feeder and crushed to 100-150mm.

Medium and fine crushing: The coarse crushing products are conveyed to cone crusher or fine crushing jaw crusher by belt conveyor, and finally the ore is crushed to below -15mm.

Core equipment: vibrating feeder, jaw crusher, cone crusher, belt conveyor.

Stage 2: Grinding and Classifying System - Achieve full dissociation of gold particles

Purpose: To fully dissociate the gold particles from the encapsulated veinstone, and to form a closed-circuit cycle through classification to control the grinding fineness.

Process:

Grinding: the crushed product enters the ball mill, which further pulverizes the ore through the impact and grinding action of steel balls.

Classification: The milled slurry flows into the spiral classifier, which utilizes the principle of sedimentation for classification. Qualified fine particles overflow into the re-election operation, and unqualified coarse particles (return sand) are returned to the ball mill for regrinding.

Core equipment: ball mill, spiral classifier (constitute a closed-circuit grinding system).

Stage III: Re-election and Separation System - the core link of gold recovery

Purpose: Adopting the multi-stage joint operation mode of " roughing - selecting - sweeping " to realize the stepwise recovery of gold particles of different particle sizes and ensure the maximization of the recovery rate.

Process:

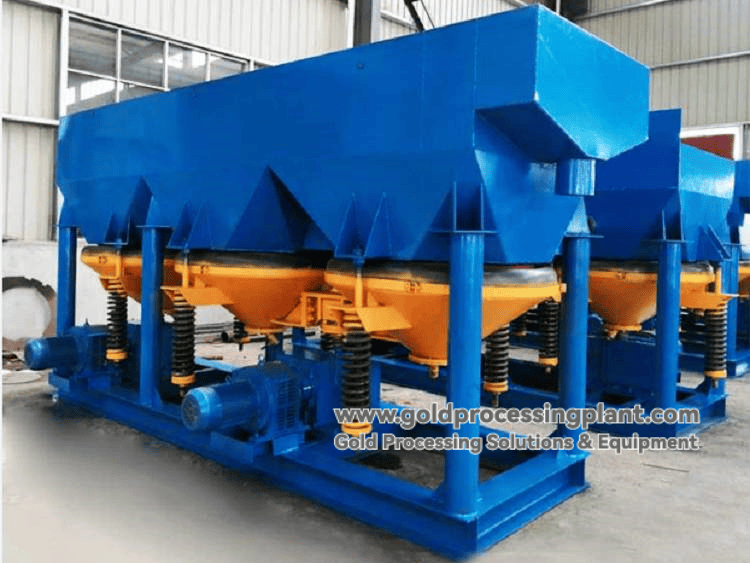

Roughing (recovery of medium and coarse-grained gold): the overflow from the classifier first enters the jigger. Utilizing the effect of alternating current, the high-density gold particles quickly sink to the bottom to become coarse concentrate, with large processing capacity and high recovery rate.

Selection (improve concentrate grade): Jig concentrate and part of the classifier overflow can enter the shaking table for precise sorting. The shaking table can produce a very high grade gold concentrate, and other heavy minerals can be separated simultaneously.

Sweep Separation (captures fine-grained gold):

Centrifugal concentrator: Highly efficient sweeping of fine-grained gold from jig and shaker tailings, utilizing a strong centrifugal force field to intensify the re-election effect, with very high recovery rates.

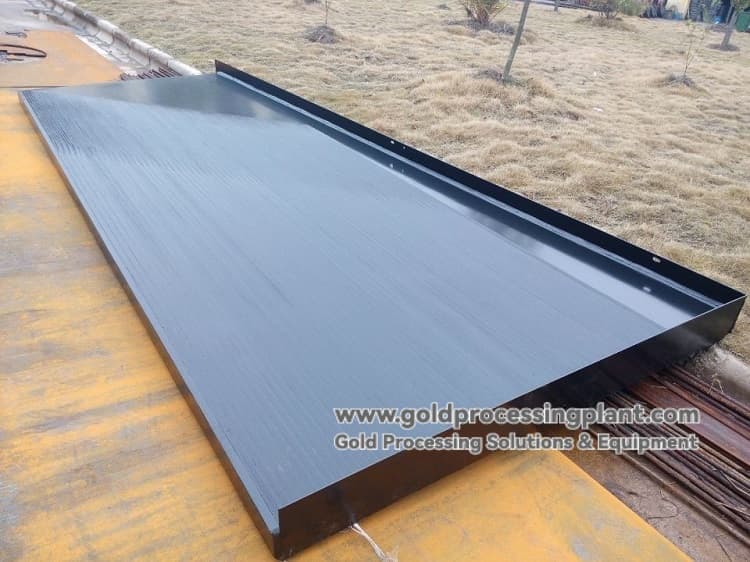

Plate chute: as a supplementary sweeping equipment with very low cost, it is covered with a trapping blanket and can be cleaned regularly to recover fine gold.

Core equipment: jigger, shaking table, centrifugal concentrator, plate chute.

Stage 4: Concentrate purification system - the last kilometer from concentrate to product

Purpose: Final purification of the enriched heavy sand concentrate to obtain high value products that can be directly sold or smelted.

Process:

Amalgamation for gold extraction: The heavy sand concentrate is fed into an amalgamation cylinder, where the gold and mercury form a gold amalgam, which is separated from other impurities. The mercury is subsequently recovered by distillation (recycling) to obtain crude gold ingots.

Final product: crude gold ingot or high grade gold concentrate, which can be sold to professional smelters for refining.

| Equipment Name | Role in the process | Core Advantages |

|---|---|---|

| Jaw Crusher | Primary coarse crushing, rock breaking and road opening | Sturdy structure, large capacity, easy maintenance |

| Ball Mill | Grinding core, realize gold particle dissociation | Stable operation, high grinding efficiency, strong adaptability |

| Spiral Classifier | Classification, desliming, closed loop | Reliable classification, large amount of sand return, good compatibility with ball mill |

| Jig | Roughing main force, recovery of medium and coarse-grained gold | Large processing capacity, high recovery rate, can work continuously. |

| Shaking table | Selection core, obtaining high grade concentrate | Extremely high sorting precision, high enrichment ratio, can produce concentrate for direct smelting |

| Centrifugal concentrator | Sweeping tool, recovering micro-fine-grained gold | Excellent recovery of -0.037mm fine-grained gold, high degree of automation |

| Plate Chute | Low-cost sweeping / small plant primary separation | No power consumption, very low investment, simple operation |

| Amalgamating cylinder | Concentrate purification, production of crude gold | Mature method, low investment, high efficiency |

Extreme recovery rate: Multi-stage combination of jigging, shaking table and centrifuge process realizes efficient recovery of gold from nuggets to micro-fine grains in the whole particle size range.

Significantly low cost: Electricity is the main energy source, no expensive chemicals are required, which significantly reduces the operation cost and tailings treatment cost.

Environmentally friendly: the whole process of physical separation, no cyanide, no toxic wastewater discharge, is a real green beneficiation technology.

Rapid return on investment: relatively low investment in equipment, simple process flow, short construction period, can be quickly put into operation and realize profits.

High flexibility: customized design according to the nature of your ore ( gold embedded characteristics, raw ore grade, budget and capacity requirements ).

A large quartz vein-type gold project in Africa

Challenge: The ore contains coarse-grained free gold, but the distribution is uneven, and the cost of cyanidation is high and the pressure on environmental protection is great.

Our solution: adopt " two-stage crushing + closed-circuit grinding + jigging roughing - shaking table selection " as the core of the gold ore re-election process.

Achievements:

Successfully stabilized the gold recovery at a high level, and the concentrate grade was much higher than expected.

Compared with the original cyanidation plan, the investment is reduced by 40% and the operation cost is reduced by 60%.

No worries about environmental protection, the project gained excellent economic and social benefits, and became a benchmark project in the region.

We provide one-stop technical support for rock and gold re-election throughout the project life cycle:

Pre-consultation and testing: Provide analysis of ore samples and small-scale tests to determine the feasibility of the process.

Customized design: process design and equipment selection and configuration based on test results and site conditions.

Equipment supply and integration: provide all core host and auxiliary equipment to ensure quality and compatibility.

On-site support: Engineers come to your door to guide installation, commissioning, and production until it reaches the standard and production.

After-sales and upgrading: long-term supply of spare parts, remote technical support and process optimization and upgrading services.

For a customized solution and detailed quotation for your mine, welcome to contact us. Our expert team will provide you with the most professional rock gold ore re-election process and technical and economic demonstration, and help your project success!

To find out more about our products and solutions, please fill out the form below and one of our experts will get back to you shortly.