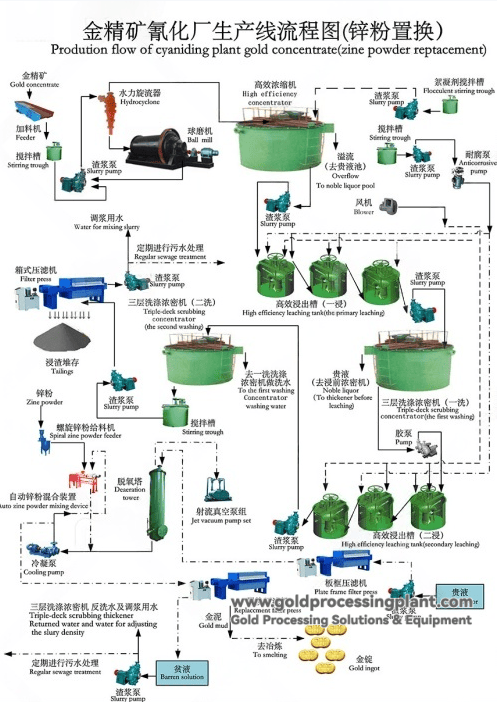

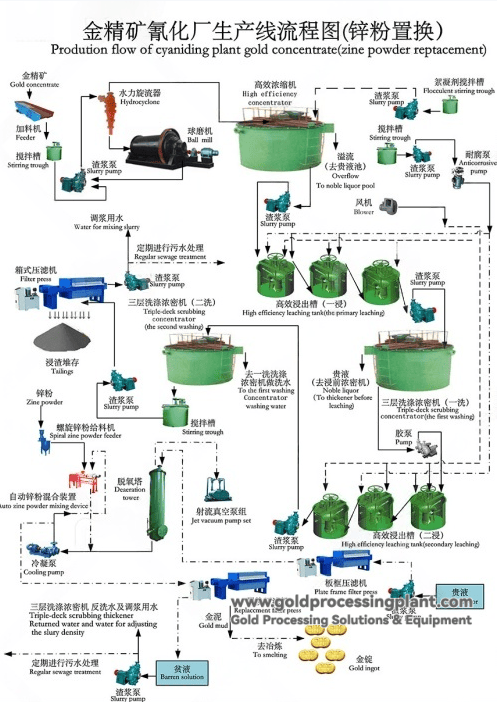

Zinc Displacement Gold Extraction Process - Precious Liquid Gold Extraction Core System

I. Product Overview

The Zinc Displacement Gold Process is a standardized system for the efficient and reliable recovery of gold and silver from gold-bearing precious liquids (usually from cyanide leaching operations). The core principle is to use zinc powder (Zn) as a reducing agent to reduce the precious metal ions (e.g., gold, silver) in the precious liquid to the metallic state, forming a gold sludge precipitation, thus realizing the extraction and enrichment of precious metals. This precious liquid gold extraction system is especially suitable for processing gold ore leach solution with high silver content, and is the key terminal equipment in gold cyanide gold extraction process.

Design processing capacity: ≤ 1200 m³/day (customized design according to project requirements)

Core advantages and features

-

High replacement efficiency and high recovery rate

-

The system integrates a high-efficiency deoxidizing tower, which completely removes the dissolved oxygen in the precious liquid, eliminates the hindering effect of oxygen on the zinc replacement reaction, and ensures that the replacement reaction proceeds sufficiently and quickly, thus guaranteeing a very high recovery rate of gold and silver.

-

Precise and uniform feeding of zinc powder

-

Adoption of automatic screw feeder realizes continuous, uniform and precise addition of zinc powder. It completely solves the problems of uneven feeding and difficult adjustment that exist in the traditional manual or mechanical adding method, and effectively reduces the residual zinc content.

-

Benefits: not only saves the consumption of zinc powder, reduces the production cost, but also avoids the excessive zinc powder affecting the quality of gold slime and improves the subsequent smelting effect.

-

Antioxidant design reduces losses

-

The zinc powder conveying and adding system adopts sealed design, which greatly reduces the contact area between zinc powder and air, effectively prevents the oxidation failure of zinc powder in the process of adding, further ensures the replacement effect and reduces the ineffective consumption.

-

High degree of automation and easy operation

-

The whole system can be automatically controlled by PLC, and the key parameters (such as zinc powder addition amount, vacuum degree, liquid level) can be monitored and adjusted in real time, which greatly reduces the intensity of manual operation and the dependence on workers' experience, and the operation is stable and reliable.

-

Excellent quality of gold slime

-

The pre-positioned precious liquid purification system (e.g. plate and frame filter) can effectively remove the suspended matters and impurities in the precious liquid, preventing them from contaminating the final product, and producing high-quality gold slime with higher purity, which is more conducive to subsequent smelting.

System composition and working principle

This zinc powder replacement gold extraction process is mainly composed of three precisely connected sections:

The first section: precious liquid purification (pretreatment)

-

Principle: The precious liquid from the leaching process usually contains solid suspensions, impurities, etc., which will deteriorate the replacement effect, contaminate the gold sludge and increase the consumption of zinc powder. In this stage, the suspended solids are completely removed from the precious liquor by means of a plate and frame filter or other precision filtration device to obtain a clear feed liquor.

-

Purpose: Ensure the cleanliness of the liquid entering the replacement system, protect the subsequent equipment, and improve the grade of gold slime.

The second section: vacuum deoxidation (core pretreatment)

-

Principle: Oxygen (O₂) dissolved in the precious liquid will react with zinc powder to generate zinc hydroxide precipitation, wrapping the surface of zinc powder to deactivate it, seriously hindering the replacement reaction of gold and silver. In this stage, a vacuum deoxidizing tower is used to efficiently precipitate and remove dissolved oxygen from the precious liquid under negative pressure.

-

Purpose: To create an ideal environment without oxygen or lack of oxygen for the replacement reaction of zinc powder, which is the key prerequisite to ensure a high replacement rate.

Section 3: Zinc powder addition and replacement filtration (core reaction)

Typical Application Scenarios

-

In gold cyanidation plant (carbon pulp plant CIP/carbon leaching plant CIL), gold is recovered from the gold-containing precious liquid generated after desorption and electrolysis.

-

Processing of gold leach solution with high silver content, zinc powder replacement method is also effective for silver recovery.

-

Recover gold from the precious liquid produced by heap leaching and pool leaching.

V. Technical service and support

We provide a full range of technical support for gold extraction from precious liquids to ensure the best performance of the system:

-

Customized design: according to your precious liquid characteristics (flow rate, gold grade, impurity content) to provide the most suitable equipment selection and configuration scheme.

-

Turnkey project: Provide the whole process service from basic design, equipment supply, installation guidance to commissioning.

-

Personnel Training: Provide comprehensive theoretical and practical training for customer's operation and maintenance team.

-

After-sales and spare parts: Provide long-term technical consultation, spare parts supply and remote diagnostic services.

If you need to get the detailed technical program, equipment configuration list and quotation of zinc powder replacement gold extraction process, welcome to contact us. Our technical engineers will provide you with professional consultation.