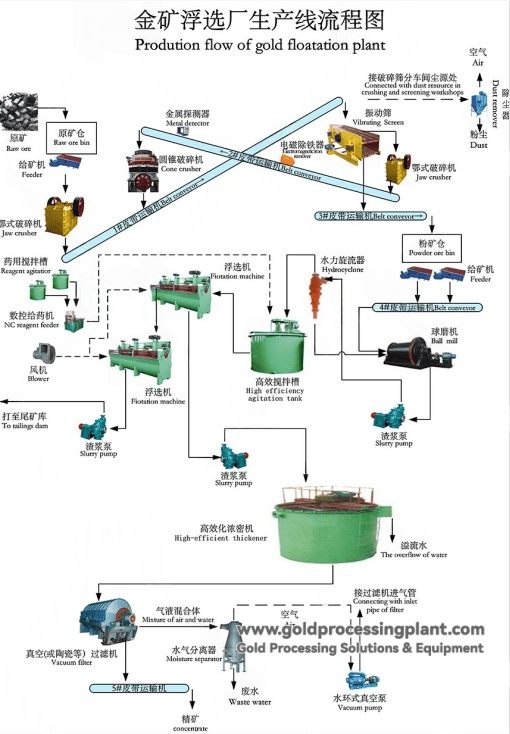

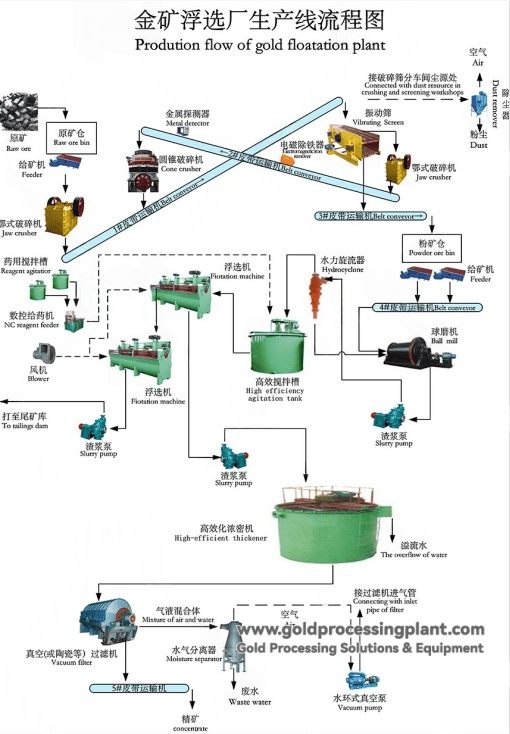

Gold ore flotation process: solution for efficient enrichment of gold in sulfide ores

Gold ore flotation process is the most widely used method for treating rock gold ores, especially gold-bearing ores of sulfide minerals with good floatability. The process maximizes the enrichment of gold into the sulfide concentrate by physicochemical methods, with high recovery rate, low cost and strong adaptability, about 80% of rock gold ores adopt flotation process.

First, the core link of gold ore flotation process flow

-

Crushing and screening system

-

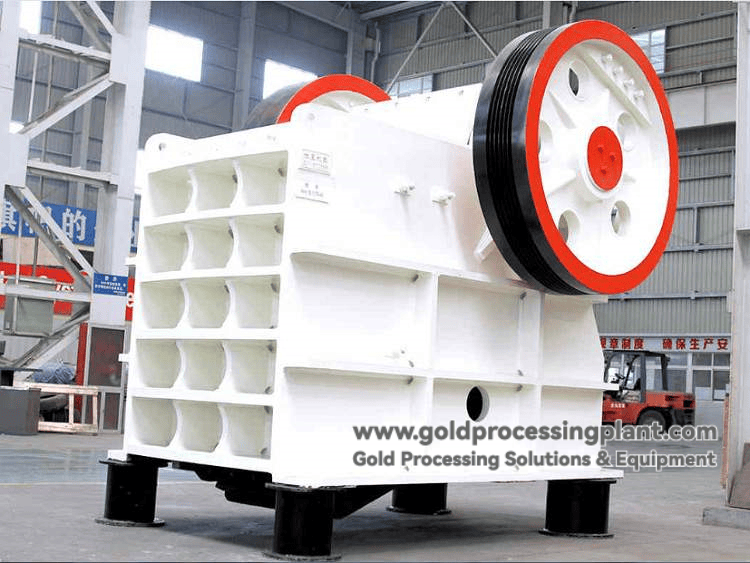

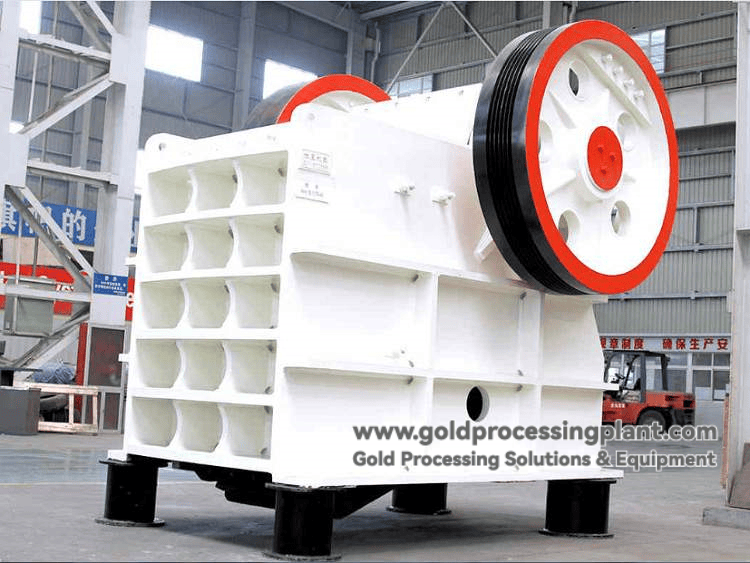

Coarse crushing: Jaw crusher crushes the raw ore to -200mm.

-

Medium and fine crushing: Cone crusher carries out medium crushing and produces -30mm products.

-

Screening: Vibrating screen constitutes a closed-circuit cycle to control the particle size of grinding.

-

Grinding and Classifying System

-

Flotation separation system

-

Product processing system

-

Concentrate dewatering: thickener + filter (or filter press), concentrate moisture <15%.

-

Tailings treatment: tailings storage or dry stockpiling, in line with environmental requirements.

Second, the technical advantages of gold ore flotation process

-

High efficiency recovery

-

Economy and energy saving

-

Strong adaptability

Applicable Ore Types

-

The best applicable ore

-

Sulfide gold-bearing quartz vein ore

-

Gold-copper, gold-lead-zinc polymetallic ores

-

Gold-bearing pyrite, toxic sand ores

-

Processable Ore

-

Unsuitable Ore

-

Coarse Gold Ore

-

Fully oxidized ore

Fourth, gold ore flotation equipment configuration

| System |

Core Equipment |

Technical Characteristics |

| Crushing System |

Jaw Crusher, Cone Crusher |

Heavy duty design, uniform product size |

| Grinding System |

Ball Mill, Hydrocyclone |

Closed circuit grinding, energy saving and high efficiency |

| Flotation System |

Mechanical agitation flotation machine |

Large filling capacity, low energy consumption |

| Pharmaceutical system |

Automatic dosing machine |

Precise control, digital display |

| Dewatering system |

Thickener, filter press |

Automatic operation, low moisture |

V. Technical points of gold ore flotation process

-

Control of grinding fineness

-

Too coarse: insufficient dissociation, low recovery rate

-

Too fine: sludge affects sorting, poor selectivity

-

Pharmacy system optimization

-

Process structure design

-

Roughing: high concentration and large dosage to ensure recovery

-

Concentration: multi-stage concentration to improve grade

-

Sweeping: reduce metal loss

Technical service support

-

Ore dressing test

-

Engineering Design

-

Gold ore flotation process design

-

Equipment selection and calculation

-

Plant layout planning, drawing design

-

Production Support

-

Gold mining equipment supply

-

Installation and commissioning guidance by engineers

-

Operator training

-

Production optimization service

Gold ore flotation is a key process for rock gold extraction, and its efficiency depends on the scientific coordination of grinding fineness, pharmaceutical system and process design. Based on the characteristics of the ore and customer needs, we can customize the whole process of gold ore flotation production line from crushing, grinding, flotation to dewatering, taking into account the technical advancement and economic benefits.

If you need to know more about gold ore flotation process design, equipment selection or to get the project plan and quotation, please feel free to contact us and our professional team will provide one-stop technical support for you!