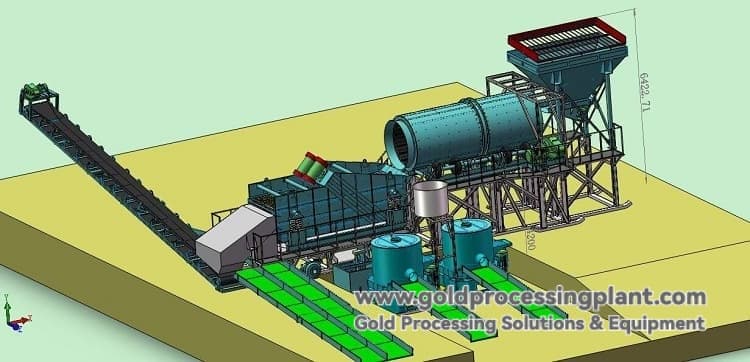

Alluvial Gold Ore Beneficiation Process Solution

I. Overview

As an important gold resource, alluvial gold ore beneficiation mainly relies on physical methods such as screening, re-election and selection, which is characterized by relatively simple process and low investment cost. However, alluvial gold ores generally have problems such as low gold grade, uneven distribution of gold particles, and easy to mud, etc. Therefore, realizing high recovery, low energy consumption and large processing capacity is the core challenge of alluvial gold beneficiation process design.

This alluvial gold beneficiation solution aims to provide highly efficient, energy-saving, reliable and economically maximized customized alluvial gold production line and process solutions for alluvial gold deposits of different sizes and ore characteristics.

II. Alluvial Gold Beneficiation Core Processes

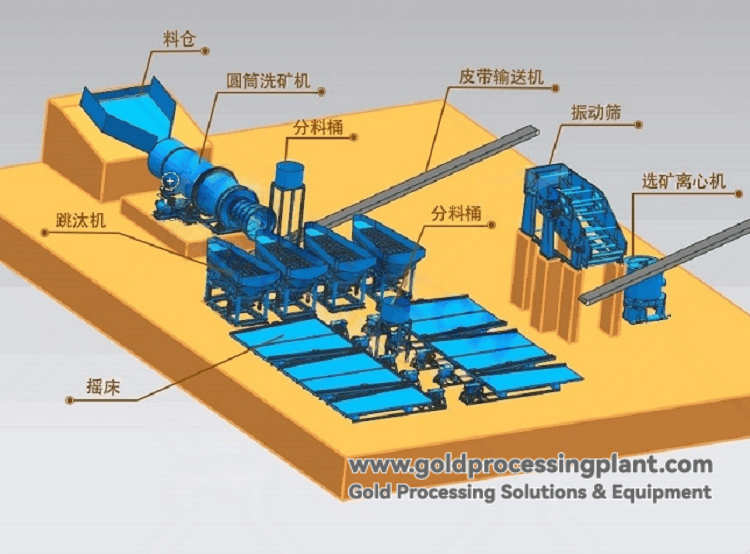

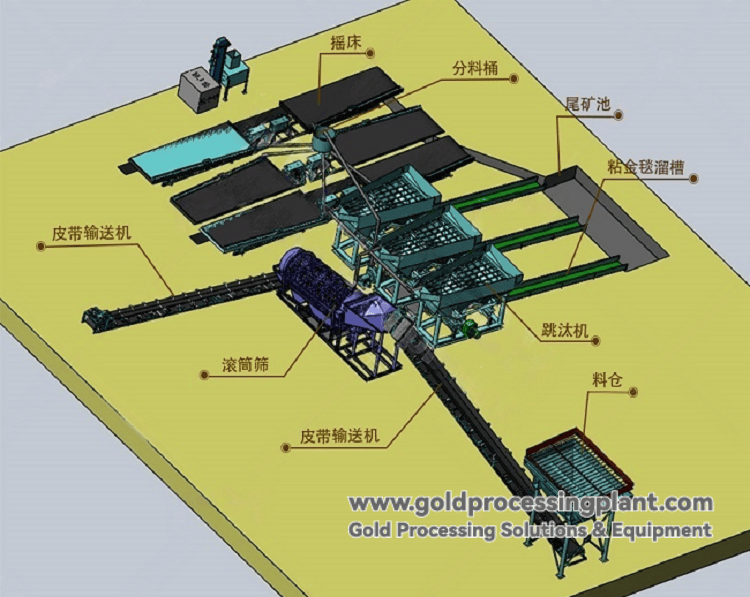

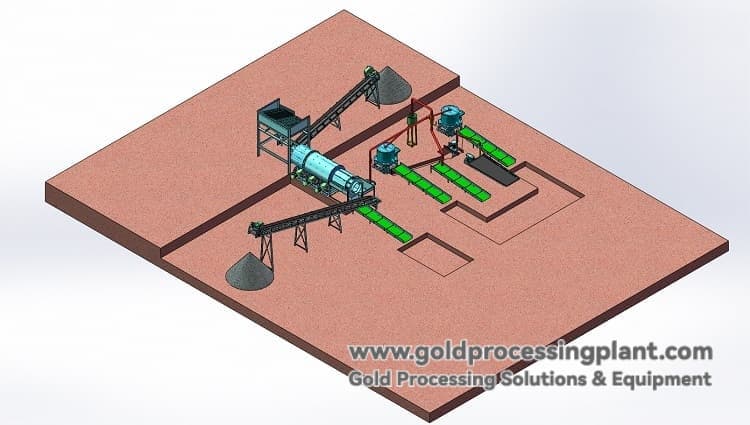

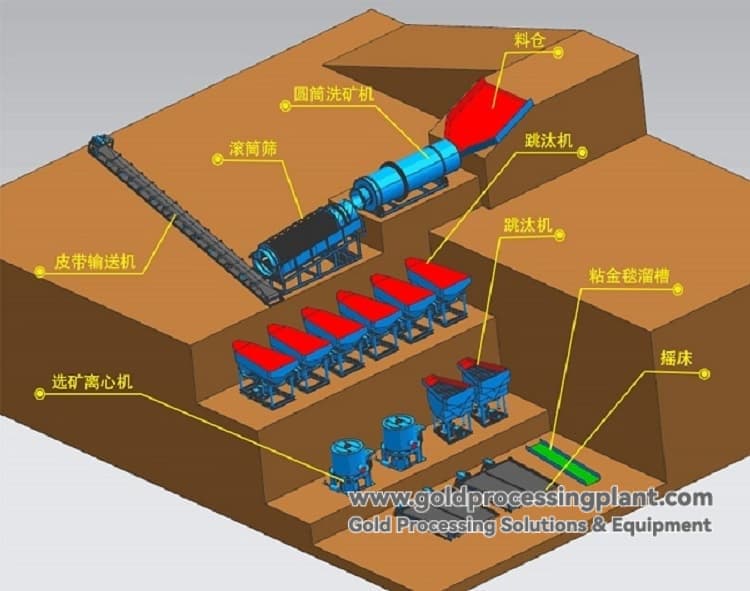

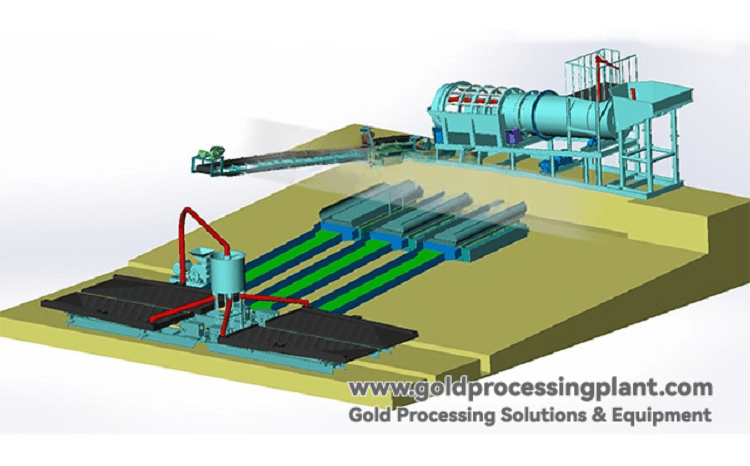

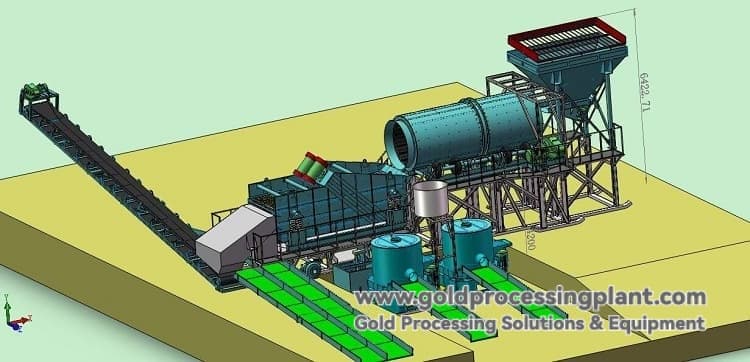

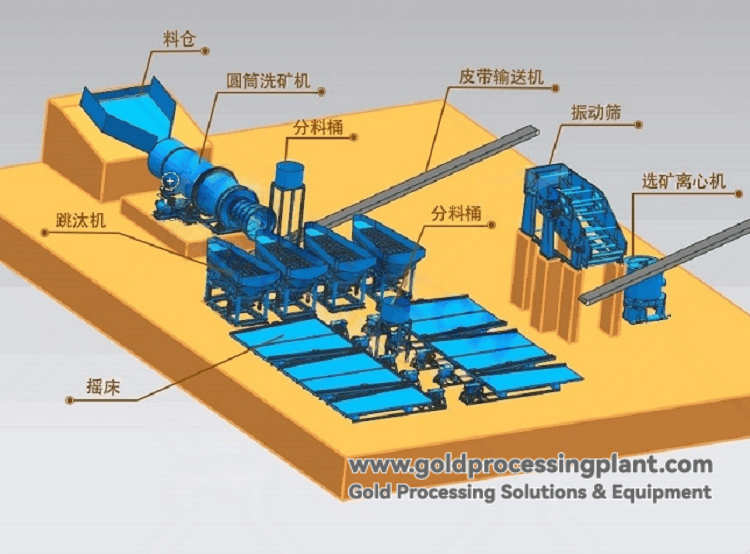

Alluvial gold beneficiation process can be divided into four core stages: pre-treatment, re-election and roughing, purification and tailing treatment.

1. Pre-treatment stage: Screening and removing impurities and washing and desliming.

-

Uniform feeding: vibrating feeder or belt conveyor is used to ensure that the materials are continuously and evenly fed into the production line to avoid equipment blockage.

-

Sieving and removing impurities:

-

Trommel screen/cylinder washer: as primary screening equipment, it can effectively screen out large gravel and waste materials and protect the subsequent equipment from damage.

-

Double-deck vibrating screen (optional): if you need to further improve the sorting efficiency, you can add a double-deck vibrating screen for finer grading of materials.

2. Re-election roughing stage (core recovery link)

According to the distribution of gold particle size, the following high-efficiency re-election equipment is used in combination:

3. Selection and purification stage

-

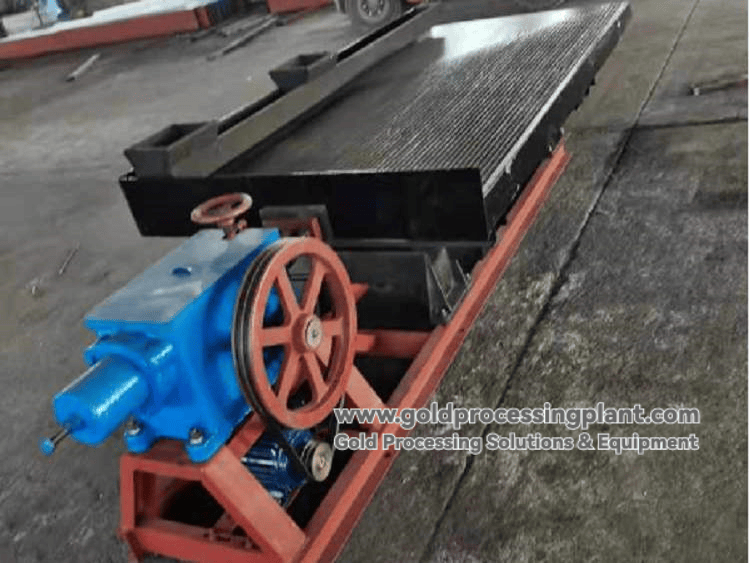

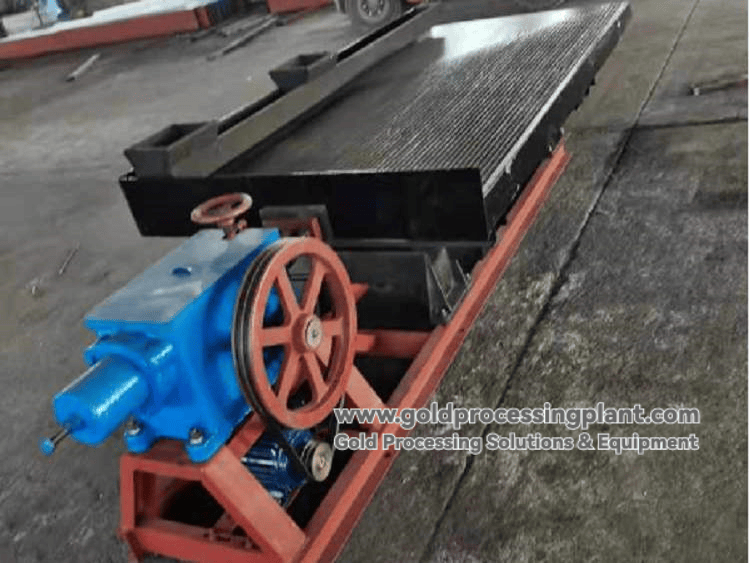

Shaking bed:

-

Amalgamation:

-

Mercury amalgamation cylinder: Highly efficient internal amalgamation equipment with >95% recovery of free gold.

-

Environmental requirements: must be fully enclosed design and equipped with activated carbon adsorption device or mercury vapor recovery system to ensure operational safety and environmental compliance.

4. Tailings treatment stage

-

Thickening: Use thickeners to increase the concentration of tailings slurry to 60%-70%.

-

Dewatering: use filter press to dewater the concentrated tailings to produce dry pile tailings with water content <15%, which can be safely stored or used for underground backfilling, realizing environmentally friendly tailings treatment.

Comparison of Customized Alluvial Gold Ore Beneficiation Process Solutions (For more customized solutions, please contact us! )

| Program Type |

Core Process |

Applicable Scenarios |

Characteristics |

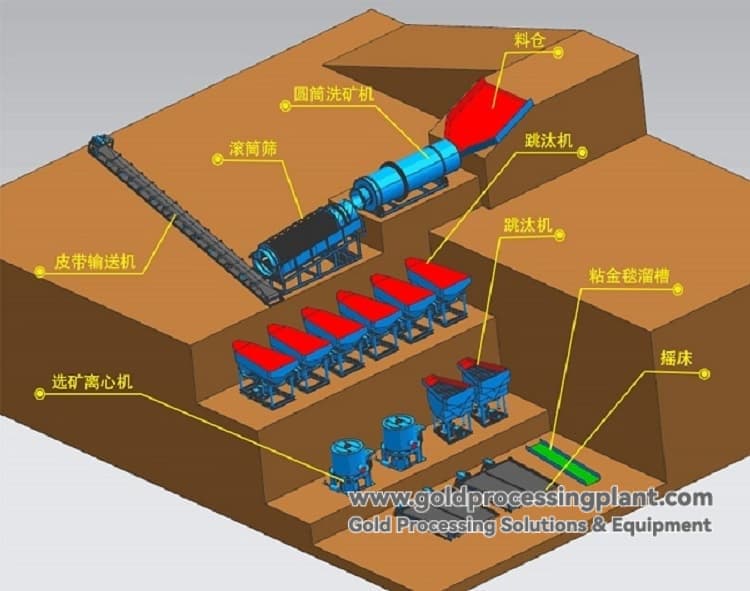

| Program 1: High efficiency recovery type |

Trommel screen → jigger → shaking table → amalgamating cylinder |

Medium-high grade, coarse-grained gold-dominated alluvial gold mine |

Very high concentrate grade, maximized gold recovery rate, high return on investment. |

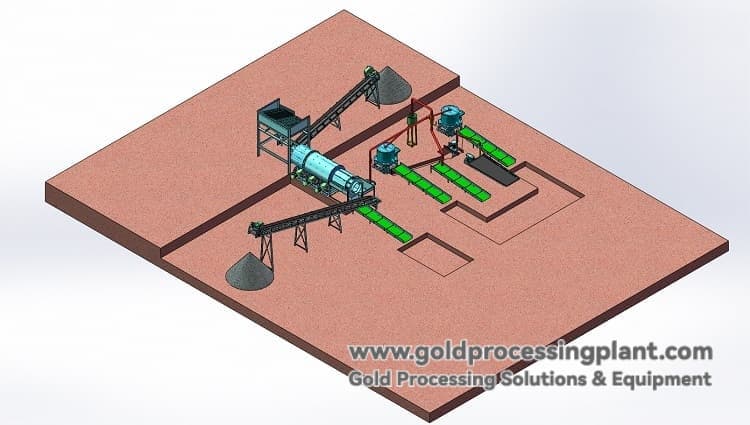

| Program 2: Large processing capacity type |

Trommel screen → jigger → centrifuge → tailings dewatering |

Low-grade, fine-grained gold-based alluvial gold mine |

Huge processing capacity (>100t/h), balancing the recovery rate and operating costs, with excellent comprehensive benefits. |

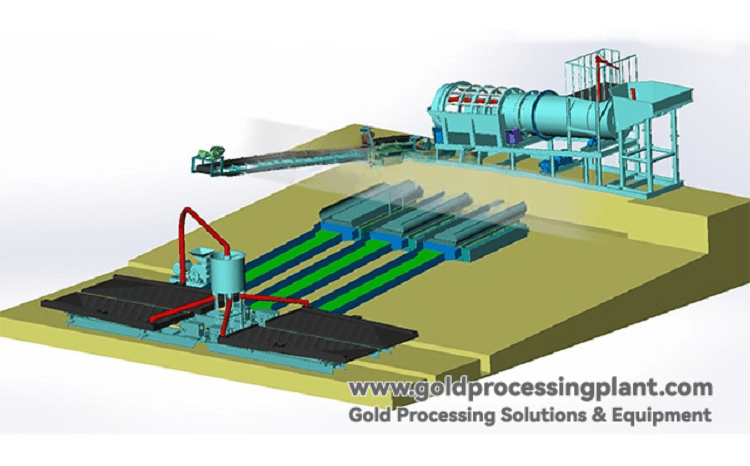

| Program three: environmental protection |

Trommel screen → jigger → shaking table → magnetic separation/reconcentration |

Areas with strict environmental protection requirements |

Completely mercury-free process, using magnetic separation or enhanced re-election to replace amalgamated mercury, in line with green mine standards. |

| Option 4: Simple mobile type |

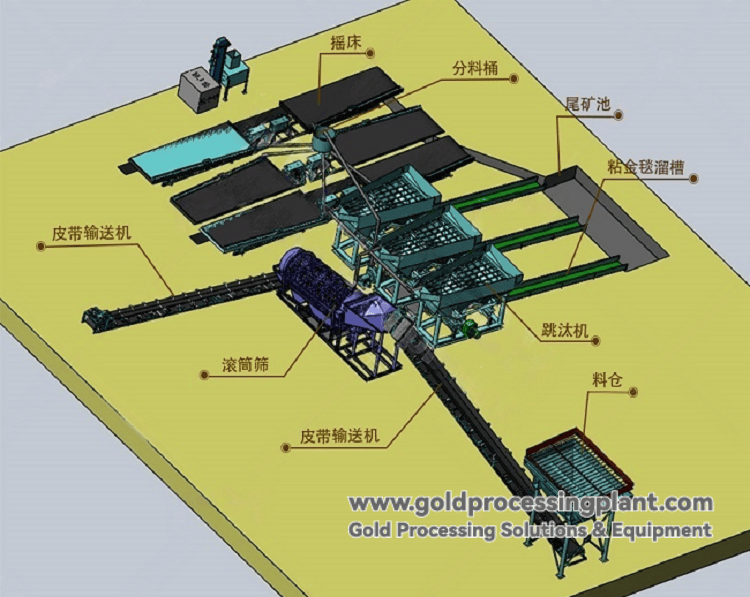

Mobile trommel screen → drumming chute/sticky gold blanket → shaking table |

Small-scale mining area with dispersed sites and high gold content |

Minimum investment, short construction period, high flexibility, can be quickly relocated, quick results. |

Typical cases

Case: a riverbed alluvial gold mining project

-

Ore characteristics: grade 0.8g/t, uneven distribution of gold particles, containing a small amount of clay.

-

Equipment configuration: vibrating feeder + trommel screen + jigger + centrifugal concentrator + shaking table + amalgamating cylinder + thickener/filter press.

V. Our core advantages

-

High recovery rate: The combined process of jigging and centrifugation realizes efficient recovery of gold particles in the whole particle size range from 0.02mm to 30mm.

-

Low operating cost: through the optimized matching of equipment and the application of non-powered equipment (such as spiral chute), energy consumption and maintenance cost are significantly reduced.

-

Modular design: The production line adopts modular structure, which can be flexibly expanded or reduced according to the demand of resources and production, reducing the initial investment risk.

The core of the alluvial gold ore beneficiation process lies in the combination of "high efficiency roughing + fine sweeping". With hundreds of successful alluvial gold mining projects, we are able to provide you with the most economical and reliable customized alluvial gold beneficiation solutions based on your ore characteristics (particle size, grade, mud content), production capacity requirements and local environmental policies.

To get the specific alluvial gold beneficiation program design, equipment selection advice and detailed quotation for your mine, please contact us now! Our expert team will provide you with professional technical support and consulting services.