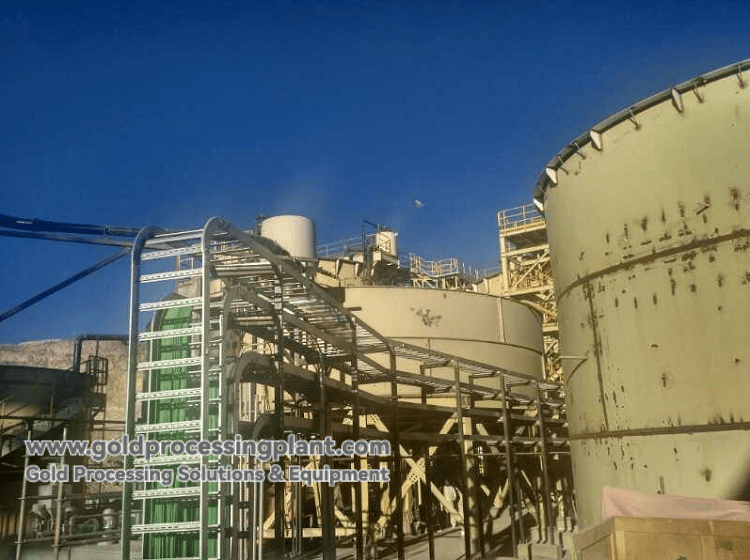

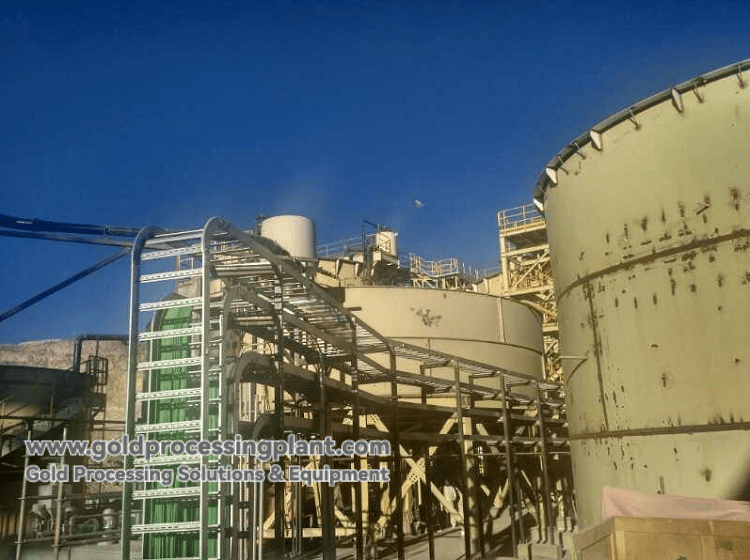

CIP Process Solution for Gold Mining

I. Process Overview

Carbon In Pulp (CIP, Carbon In Pulp) is an advanced process for recovering gold directly from cyanide slurry by adsorption using activated carbon. The CIP production line can efficiently extract gold through the core steps of crushing and grinding, leaching and adsorption, desorption and electrolysis, carbon regeneration and smelting, etc. It has high recovery rate and strong adaptability, and is especially suitable for treating flotation gold concentrates, reelected gold tailings and muddy oxidized gold ores.

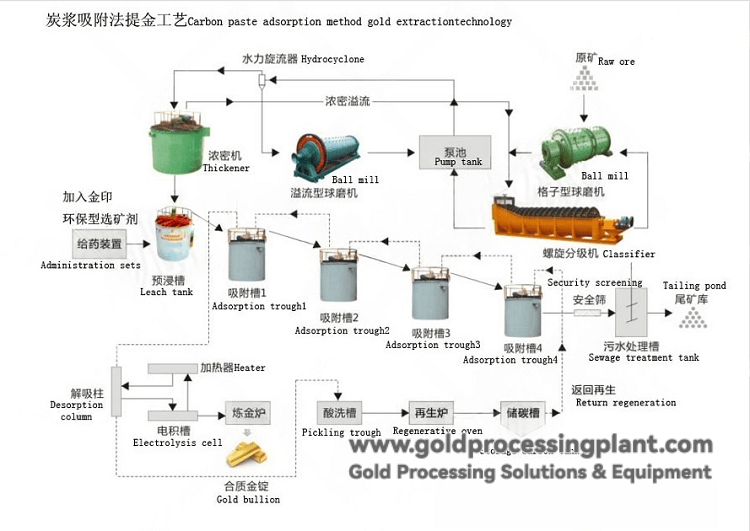

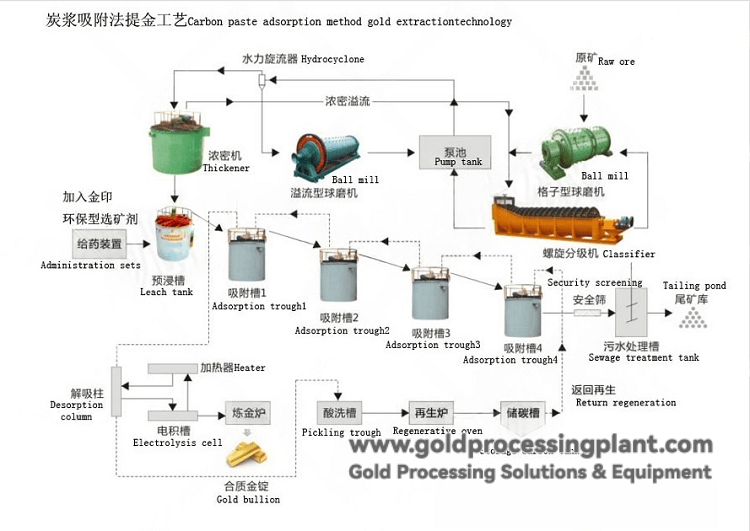

II. Gold CIP process flow details

-

Ore preparation stage

-

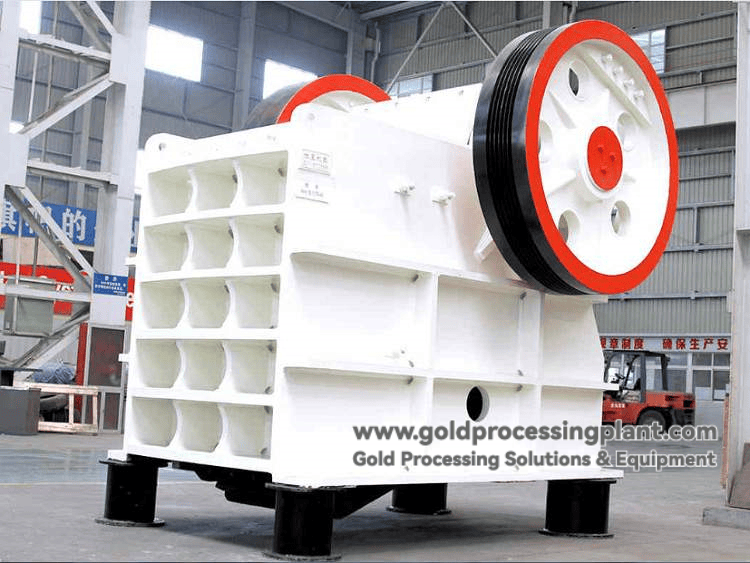

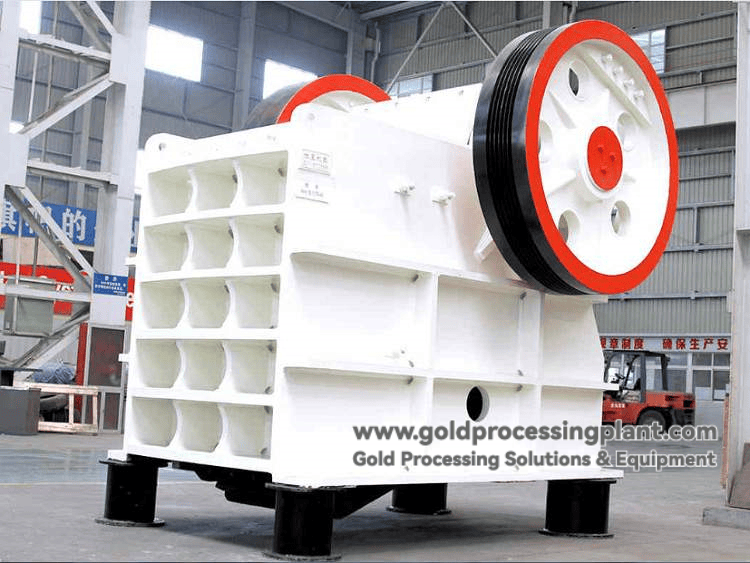

Crushing system: the multi-stage crushing process of "Jaw Crusher + Cone Crusher" is adopted to ensure that the particle size of the ore meets the requirements for grinding, which is highly efficient and energy-saving.

-

Grinding system: A closed-circuit grinding process consisting of "ball mill + hydrocyclone" is adopted to precisely control the grinding fineness (usually -200 mesh accounts for 85%-95%), creating the necessary conditions for efficient leaching.

-

Slurry pre-treatment

-

Debris removal: Use debris removal screen to remove wood chips and debris to prevent damage to pump valves and clogging of the screen mesh.

-

Thickening and adjusting slurry: Optimize the slurry concentration to 40-45% by means of a high-efficiency thickener, and add lime to adjust the pH value to 10.5-11.5 to create a stable environment for cyanide leaching.

-

Leaching and Adsorption System (CIP Core)

-

Leaching tank set: 6-9 double impeller leaching tanks are connected in series and filled with oxygen-enriched air to ensure that cyanide reacts fully with gold to complete dissolution.

-

Activated Carbon Adsorption: High-quality coconut shell activated carbon is added to the leach slurry. The carbon moves counter-currently between the tanks, and fresh carbon is added from the last tank to gradually adsorb the enriched gold into gold-carrying carbon.

-

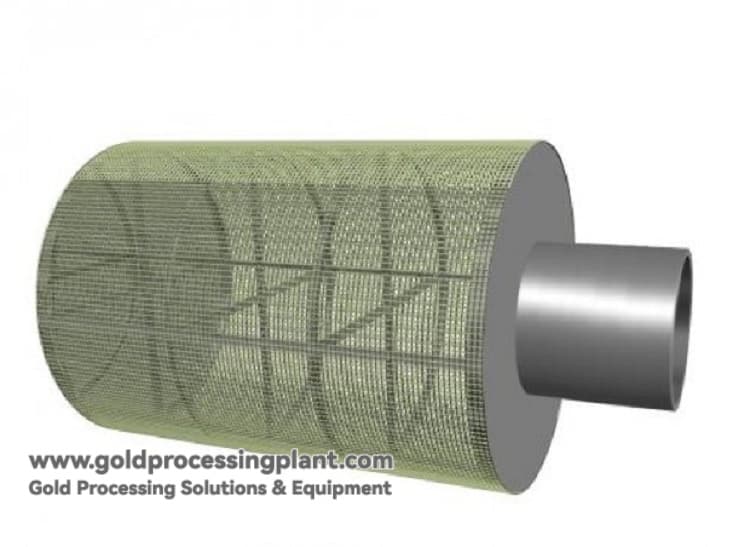

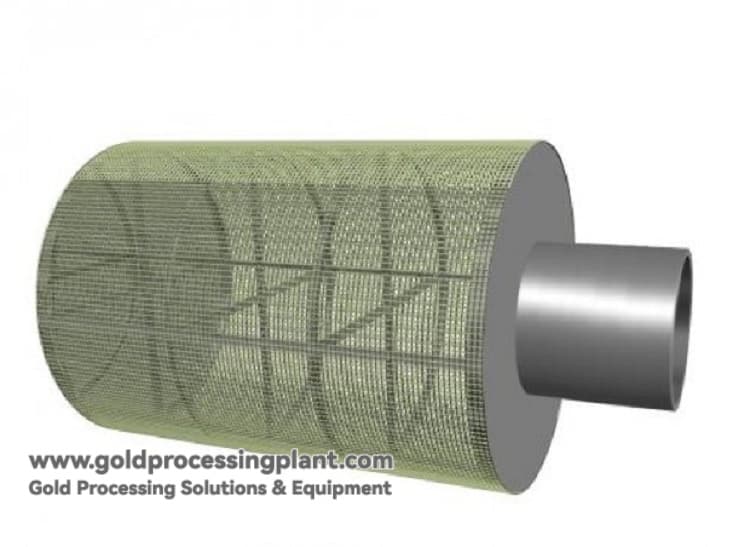

Carbon screen system: A high-efficiency carbon screen is set after each adsorption tank to separate the slurry from the activated carbon and control the carbon loss.

-

Gold-carrying carbon treatment system

-

Desorption electrolysis: The gold-carrying carbon enters the high-temperature and high-pressure desorption electrolysis system. Under the condition of 150℃ and 0.5MPa, gold is desorbed from the charcoal by using cyanide-free desorption solution, and the gold is then deposited on the cathode plate in the electrolyzer to form gold sludge.

-

Charcoal regeneration system: The desorbed lean charcoal is regenerated by acid washing and high temperature rotary kiln to restore the activity and return to the adsorption system for recycling.

-

Smelting and refining

-

Gold slime treatment: collect electrolyzed gold slime, after acid washing and removing impurities, put it into medium frequency smelting furnace for high temperature smelting.

-

Ingot casting: the molten gold liquid is cast into standard gold ingots with purity of 99.6% or above.

III. Technical advantages of CIP process for gold mine

-

High efficiency recovery: activated carbon countercurrent adsorption, gold recovery rate as high as 92%-96%.

-

Energy saving and environmental protection:

-

Closed design, reduce cyanide volatilization.

-

Carbon regeneration cycle, reduce consumption.

-

Cyanide-free desorption, environmentally friendly.

-

Intelligent control: PLC/DCS automated control system is adopted to monitor key parameters such as pH, concentration and carbon density online to realize stable production.

-

Stable and reliable: the equipment is made of corrosion-resistant materials, and the process is mature, safe and reliable operation.

Fourth, the core advantages of high-efficiency desorption electrolysis system

| Advantage |

Specific performance |

| High efficiency |

Desorption rate >96%, the grade of poor carbon is reduced by 50%-75% compared with the conventional system. |

| Rapid |

High temperature (150℃), high pressure (0.5MPa), desorption time is only 10-12 hours, shortened by more than 50%. |

| Low consumption |

High thermal efficiency, total power consumption is only 1/2 - 1/4 of conventional system. |

| No cyanide |

No need to add NaCN in the desorption solution, low cost and no pollution. |

| Safety |

Three-fold safety protection: intelligent control, automatic pressure-limiting release mechanism, and safety valve. |

V. Recommended configuration of key equipment for CIP in gold mine

| System |

Core equipment |

| Crushing |

Jaw Crusher, Hydraulic Cone Crusher |

| Grinding |

Overflow Ball Mill, Hydrocyclone Unit |

| Adsorption |

Double impeller energy-saving leaching tank, high-efficiency carbon screen |

| Desorption and Electrolysis |

High-temperature and high-pressure desorption column, electrolyzer group |

| Carbon regeneration |

Acid washing tank, high temperature regeneration kiln |

| Smelting |

Medium frequency smelting furnace, gold ingot casting molds |

VI. Production examples and indicators

An oxidized gold ore project (raw ore grade: 3.5 g/t):

VII. Applicability and Economic Benefits of CIP Process for Gold Ore

VIII. Our technical service support

We provide one-stop solution for CIP process of gold mine:

-

Engineering design: full-flow process design, site planning and drawings design.

- Equipment supply: non-standard equipment design and selection, gold mine CIP equipment manufacturing supply

-

Production Support: Engineer on-site installation and commissioning guidance, personnel training, production optimization.

-

Environmental protection program: cyanide wastewater treatment system, tailing pond design.

For detailed gold CIP process solutions or technical consultation, please contact our professional team, we will provide you with the best gold CIP program configuration and quotation.