Rare and precious metal ore beneficiation process flow solutions

I. Overview: Unlocking the core value of scarce resources

Rare and precious metals (such as gold, silver, platinum group metals and rare and rare earth metals) are strategic resources for high-end manufacturing, new energy and national defense technology. Their ores are generally characterized by extremely low grade, complex mineral composition, close symbiotic relationship, and fine embedded particle size, which puts forward high requirements for beneficiation technology.

We provide a full value chain of rare and precious metal beneficiation solutions from mineralogical research, selectivity testing, process design, high-end equipment selection to project delivery and operation support. With deep technical accumulation and rich project experience, we are committed to solving the extraction problems for our clients, maximizing the comprehensive utilization value of resources, and ensuring the best economic benefits for the projects.

Second, rare precious metals core beneficiation process: customized joint process art

No single method can be used for the recovery of rare and precious metals, and it must be customized according to the characteristics of the ore. We are well versed and flexible in utilizing all of the following processes and excel in combining them into highly efficient and synergistic combined processes.

1. Pre-treatment stage: laying the foundation for efficient sorting

-

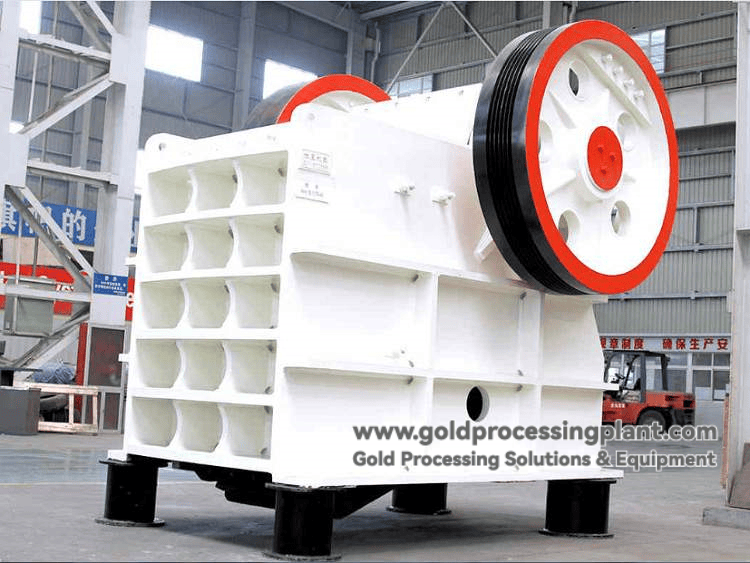

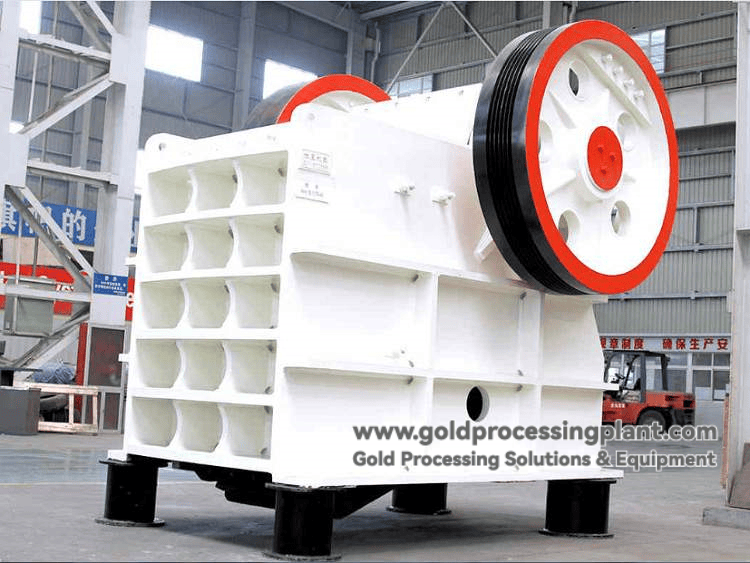

Crushing and screening: adopting the " three-stage and one closed-circuit " process (Jaw Crusher + Cone Crusher + Vibrating Screen), the ore is efficiently crushed to less than -15mm, which provides the ideal feed for grinding and avoids the metal loss caused by over-crushing.

-

Grinding and Classification: Ball mill and hydrocyclone (or spiral classifier) are used to form a closed-circuit system, precisely controlling the fineness of grinding and realizing full monomer dissociation of the target minerals, while minimizing energy consumption.

2. Sorting and enrichment stage (core technology link)

We accurately match the most effective sorting technology according to the physical and chemical properties of the target metals:

| Sorting process |

Application Scope and Characteristics |

Core Equipment |

| Gravity Separation |

First choice for coarse-grained high-density minerals such as gold and silver. Low investment, low cost, environmentally friendly, often used as a means of pre-enrichment. |

Nelson/Falcon centrifugal concentrators, jigging machines, shaking tables |

| Flotation Processes |

Core technology for the recovery of most rare and precious metals. High sorting efficiency and extremely adaptable. Customized pharmaceutical regimes are the key to success. |

High-efficiency inflatable mechanical agitation flotation machine, flotation columns |

| Cyanide Leaching |

Classic and efficient method for gold and silver extraction. High gold recovery by CIP/CIL process. |

Leaching agitation tank, activated carbon adsorption system, desorption electrolysis device |

| Magnetic Separation |

Used to separate magnetic minerals (e.g. tantalum niobium ore, monazite) or remove magnetic impurities. |

High gradient magnetic separator, strong magnetic field magnetic separator |

| Electrostatic separation |

Used for the selection and purification of coarse concentrates, utilizing the difference in electrical conductivity for sorting with high precision, especially for tantalum-niobium and zircon. |

High voltage electric separator |

| Combined process flow |

The soul of coping with complex co-associated ores. For example, the combination of re-election-flotation, flotation-leaching, magnetic separation-flotation-electrowinning, etc. realizes comprehensive recovery of multi-metals. |

Customized according to process design |

3. Product processing and refining stage

-

Thickening and dewatering: adopt high efficiency thickener and ceramic vacuum filter or plate and frame filter press to obtain low moisture filter cake, reduce transportation cost or prepare for drying.

-

Drying and packaging: according to product requirements, rotary kiln or airflow dryer is used for drying.

-

Smelting and purification: Provide technical solutions for pyrometallurgy (for precious metals) and hydrometallurgy (for rare and rare earth metals) to produce high-purity metal or compound products.

III. Advantages of our solutions

-

Leading technology and professional expertise:

-

With a team of professional engineers in rare and precious metal beneficiation, we provide accurate technical support from test to production.

-

We have mastered exclusive pharmaceutical formulations and joint flow processes, and are especially good at processing extremely low-grade and complex co-associated ores.

-

Excellent economic benefits:

-

High overall recovery rate: through the combination of multiple processes, we ensure the full recovery of the main metal and associated valuable metals, and "squeeze out all of them".

-

Low operating costs: Optimized process design significantly reduces energy, chemical and maintenance costs.

-

Short payback period: Maximized revenue from efficient recovery ensures rapid project profitability.

-

Flexible and modular design:

-

The solution can be flexibly configured and modularly expanded according to the processing scale, ore nature, and investment budget.

-

Mobile, modular plant solutions are available for exploration or decentralized sites.

-

Green & Sustainable:

-

Prioritize the use of cyanide-free or cyanide-reduced environmentally friendly processes.

-

Provide tailings dry discharge, wastewater recycling and waste residue harmless treatment solutions to help the construction of green mines.

IV. Successful Cases: Proof of Technical Strength

A large-scale comprehensive rare and precious metal mine project

-

Challenge: The ore contains gold, silver, platinum, rhodium and other extremely valuable metals, but the grade is low, the embedded relationship is complex, the recovery rate of the traditional single process is extremely low, especially the economic recovery of platinum and rhodium is a major worldwide problem.

-

Our program:

-

Through detailed process mineralogical research, we clarified the state of the metals.

-

Innovative design of the " re-election pre-tailing - flotation comprehensive enrichment - concentrate grading leaching (cyanidation + special leaching) - magnetic separation / electro-electrowinning separation " joint process.

-

Achievements:

-

The recovery rate of gold and silver has reached the leading level in the industry.

-

Successfully realized the industrialized and stable recovery of platinum, rhodium and other extremely difficult to extract metals, breaking the technical barriers.

-

The project has become a model of comprehensive utilization of resources, bringing customers economic benefits far beyond expectations.

V. Full life cycle technical service and support

We promise to be your long-term technical partner and provide support throughout the project:

-

Laboratory research and feasibility demonstration: ore selectivity test, continuous expansion test, providing authoritative test reports and process flow suggestions.

-

Engineering design and planning: full-flow process design, equipment layout, non-standard design, site planning, drawing design.

-

High-end Equipment Supply and Integration: Provide the world's leading core rare metal beneficiation equipment manufacturing and supply.

-

Project construction and commissioning: expert team on-site guidance for installation, commissioning, trial operation until reaching the standard and production.

-

Personnel Training and Operation Optimization: Train skilled operation and maintenance teams for customers and provide continuous production optimization suggestions.

-

After-sales service and upgrading: fast spare parts response, remote diagnosis, technical upgrading and transformation services.

Please provide your ore samples or mineralogical information, and our expert team will conduct a preliminary assessment and customize the most economical and efficient rare and precious metal beneficiation solution for you. Contact us now to get the exclusive technology rare precious metal beneficiationprocess flowscheme with detailed quotation!